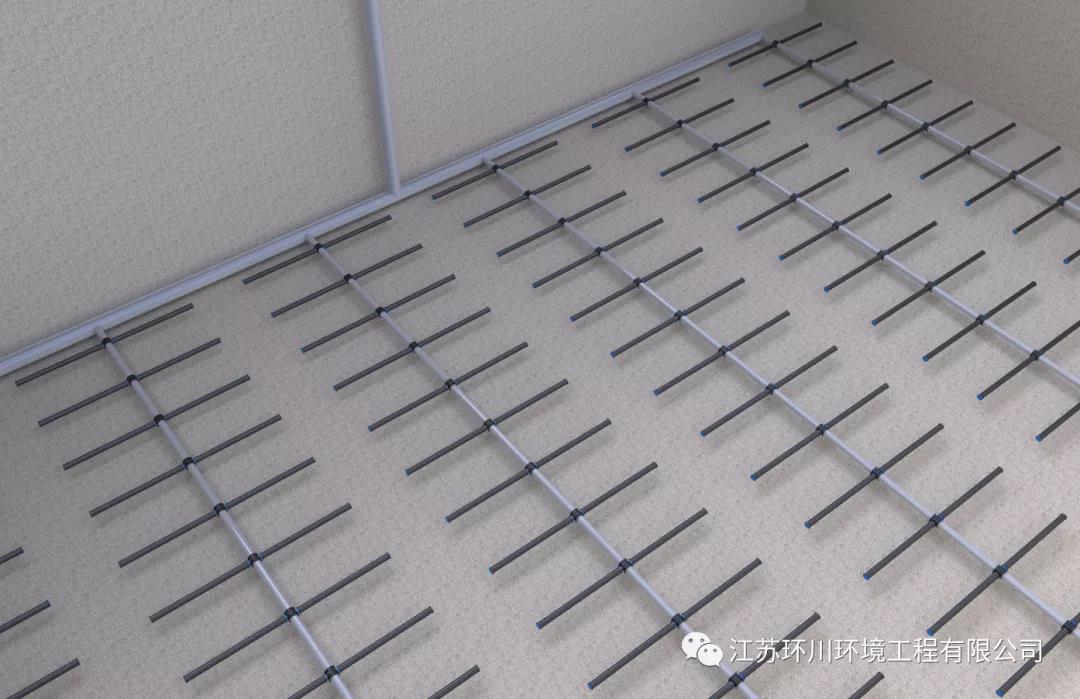

1、 Bottom installation

Connected to the main ventilation pipe at the bottom of the pool, the main ventilation pipe at the bottom of the pool is further divided into several ventilation branch pipes; The main ventilation pipe and branch pipe at the bottom of the pool are fixed to the bottom of the pool through adjustable brackets and expansion screws, and the aerator is installed on the ventilation branch pipe; Distributed in units. OTT/D-REX disc aerators and MAGNUM tubular aerators can be used.

There are certain requirements for the strength of the concrete at the bottom of the aerobic tank, and it is necessary for the manufacturer to stop production, drain water and mud, and clean the bottom of the tank before implementation. The loss of production and labor costs are huge.

2、 Can enhance installation

The ventilation main pipe spans across the aeration tank, and each set of aerators is lifted from the ventilation support riser to the bottom of the tank. Each set of ventilation support riser is separately equipped with a detachable joint, usually using MAGNUM tubular aerators.

System installation

Support installation with water, no need for manufacturers to stop production, drainage and sludge discharge, no requirement for concrete strength at the bottom of the pool, greatly reducing production losses and labor costs.

system maintenance

Easy to maintain, each set of aerators can be disassembled separately at water depth for maintenance and replacement. Simple and easy to implement, no need to stop production and drainage, can be operated online with water.

3、 Bottom mounted VS can enhance installation

Condensation drainage system:

Bottom installation: Each unit needs to be equipped with a separate condensate drainage system.

Installation can be improved: As the system point is an aerator, there is no need to set up a condensate drainage system.

Damage method:

Bottom installation: Large area damage in a regional pattern. Due to the modular distribution of the system, if one product is damaged, it will cause water and mud to enter the pipeline system, resulting in the paralysis of the entire aeration unit.

Can be upgraded for installation: individually damaged. Due to the independent distribution and non-interference of all aerators, damage to one product will not affect other products in the system.

Investment cost:

Bottom installation:

1. The ventilation pipeline is made of UPVC or ABS, with a general service life of about 5 years. The single investment cost is low, but multiple investments are required.

2. The long installation and maintenance cycle results in significant production losses and labor costs, as well as high environmental pressure.

Summary: Low investment, but high overall cost.

Can enhance installation:

1. The ventilation pipeline is made of carbon steel or stainless steel material, with a long service life and no need for replacement, but requires a large investment.

2. Easy installation and maintenance, short cycle. The corresponding shutdown losses and labor costs are small.

Summary: The cost of investing in pipelines is relatively high, but the overall cost is low.

in summary:

The aeration system can be installed in a raised manner, which is superior to traditional bottom installation in many aspects.